Main Products

Your Trusted Partner in Industrial-Grade passive components.

CHANGZHOU YUANSHENG TECHNOLOGY CO., LTD

Empowering Industries with Precision Passive Components

As a Jiangsu-based pioneer in passive electronic solutions since 2013, we deliver mission-critical EMC components for industrial automation, automotive systems, and next-gen applications. Our expertise spans VFD systems, servo technologies, and power supply innovations, with core products including wound rod inductors, high-frequency transformers, and precision resistors.

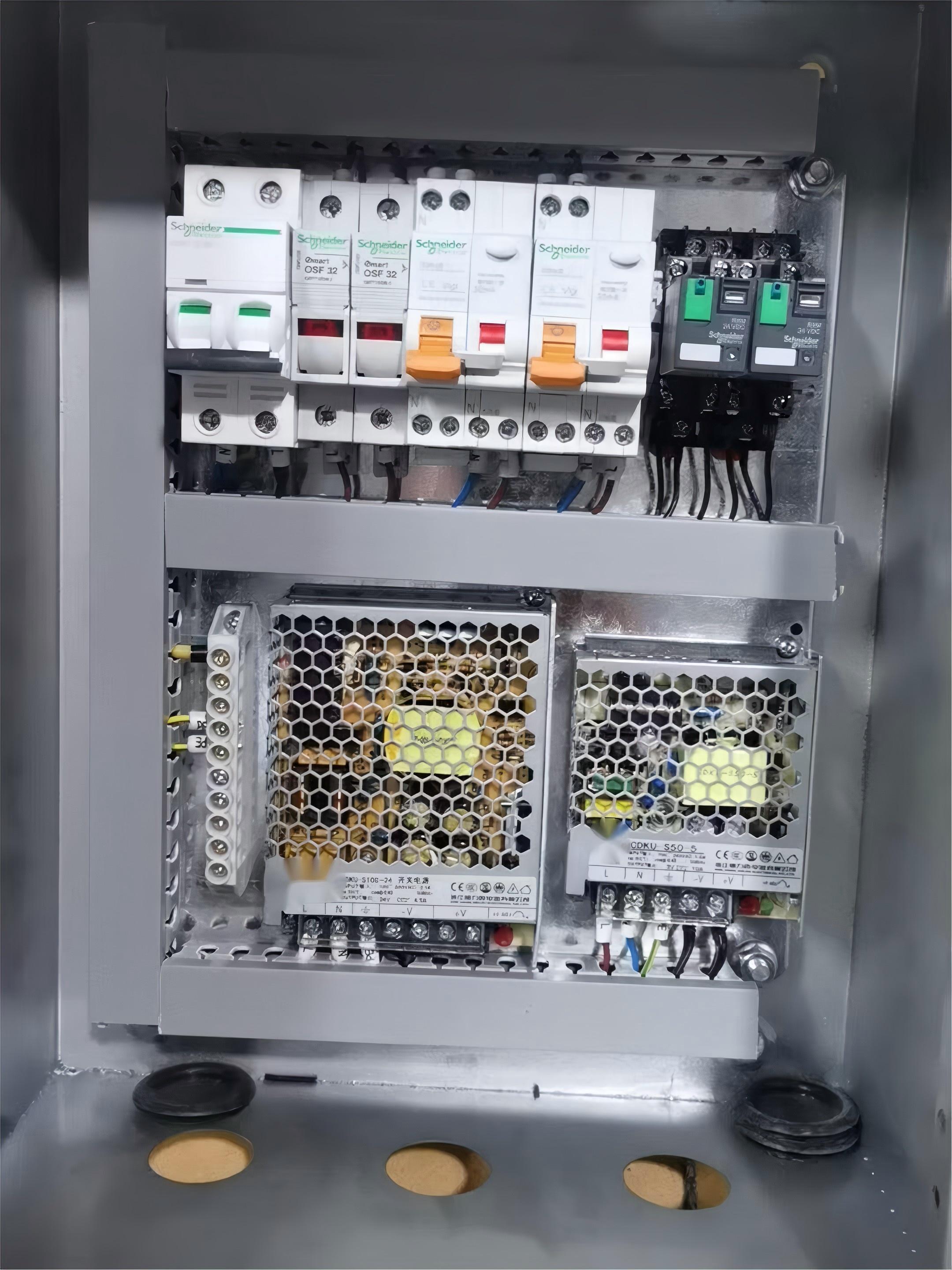

Backed by ISO9000/TS16949-certified manufacturing across three strategic hubs (Nanjing, Bangbu, HuaiAn), we combine R&D agility with rigorous quality control. Over 80% of production lines utilize automated systems to ensure <0.2% defect rates while maintaining flexible customization capacities.

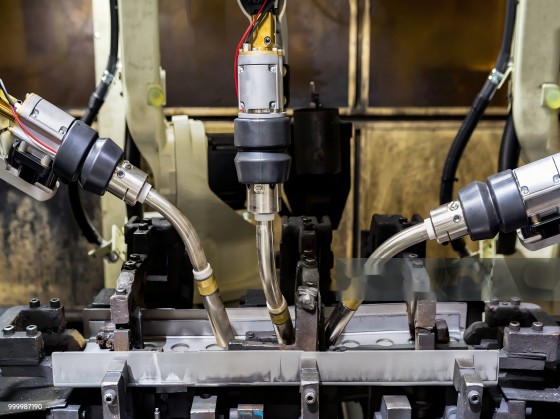

Trusted by global leaders in robotics, EV manufacturing, and smart infrastructure, we've achieved 40% YOY growth through engineering-led partnerships. Every component embodies our dual commitment: solving EMI challenges today while co-developing solutions for tomorrow's electrified world.

Application Fields

—

Trusted by Leading Importers, Distributors, and Wholesalers Worldwide, We Deliver High-Quality Current Shunts, Open-Air Shunt Resistors, Aluminum Braking Resistors, and Custom Coils for Industrial Automation, Motors, Power Supplies, and Inverters.

-

Integrated Current Sensing Busbar for Inverter and Motor Control Systems This integrated current sensing busbar combines high-conductivity copper pathways with a built-in precision shunt, delivering accurate current measurement and reliable power distribution in a single compact unit. Designed specifically for industrial motor drives and inverter systems, it simplifies wiring, saves space, and enhances real-time monitoring. ✅ Key Advantages Accurate current sensing – Built-in shunt provides real-time feedback for control systems Compact integration – Combines conduction and detection functions in one structure High reliability – Withstands thermal stress and high current loads in demanding environments Improved safety – Enables overload protection and better energy efficiency Customizable design – Dimensions, resistance, and terminal t...

-

Solutions for Inductive Noise Mitigation

-

Function Setting ACLT-38100 Function Setting 1. Load power setting: 0-1000KW continuously adjustable, simulating communication equipment of various powers. 2. Load time setting: 0-99 hours continuously adjustable, set according to maintenance needs. 3. Load minimum voltage alarm setting: set according to maintenance needs. 4. Load maximum voltage alarm setting: set according to maintenance needs. 5. Parallel setting function: up to 9 units can be connected in parallel and work at the same time. 6. Built-in storage function: continuously record the test data of the last three hours, simple and convenient operation. 7. Software analysis function: use Chinese Windows operating environment, Chinese culture, graphical and control system, and automatically generate test reports. Application field Widely used in communications, civil aviation, banking, securities, railway ...